What is a Sigma Mixer Used For

#image_title

The Sigma blade mixer is an ideal equipment for kneading, mixing, vulcanization and polymerization of high-viscosity and elastic-plastic materials. The kneader can be used to produce silicone rubber, sealant, hot melt adhesive, food rubber base, pharmaceutical preparations, etc. The kneader is a special kind of mixing and stirring equipment. The most commonly used is to use two Σ paddles, which are arranged side by side with a tangential differential speed, that is, the speed of one paddle is fast, and the speed of the other paddle is slow, so as to generate shear. Shearing force, different paddle speeds enable the mixed materials to be sheared rapidly, so that the materials can be mixed evenly.

Sigma mixer has Wide range of applications, especially suitable for chewing gum, bubble gum, toothpaste, plastics, rubber, silicone rubber, dyes, pigments, inks, food gum bases, pharmaceuticals, architectural coatings, carbon, cellulose, high-viscosity sealants, neutral glass Glue, aluminum silver paste, silica gel, paper pulp, cellulose, battery paste, dye, silicone resin, cosmetics and other industries.

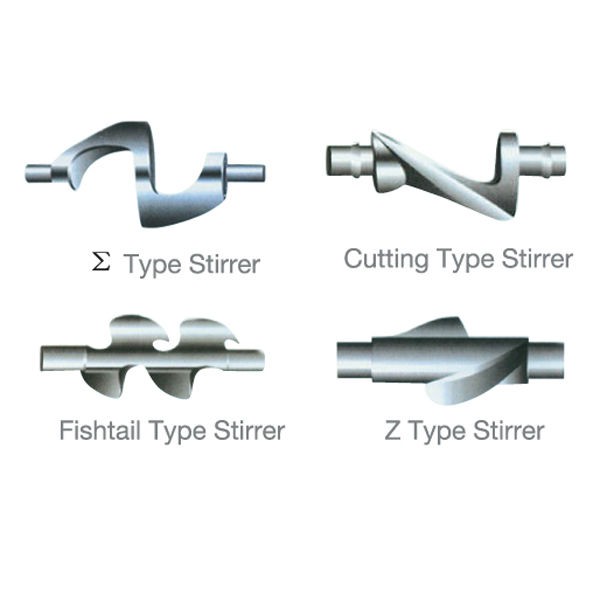

Sigma blade mixer mainly have four types of blade design

1. The fishtail type stirrer is suitable for the kneading operation of cellulose materials.

2. The Z-type stirring paddle is also called the simple type stirring paddle. It has a simple shape and is used for dispersing and mixing the pigment in the resin under the condition of high viscosity.

3. The cutting type stirrer is the strongest impeller, which is suitable for kneading operation of ultra-high viscosity substances under the condition of high power and heavy load. When cutting type stirring paddles are used, most of them adopt a tangential arrangement of two paddles. Applicable materials: rubber, iron oxide, magnetic recording materials, etc.

4. Σ-type stirrer is the most general type, it is suitable for the kneading operation of external substances that must have a large movement in the kneading and tank, mainly for the arrangement of two overlapping paddles, especially for the extrusion dehydration operation In some cases, it is most suitable to use a Σ-type stirring impeller. Applicable materials: chewing gum, chocolate, glass glue, sealant, hot melt glue, butyl glue, manhole cover, carbon material, etc.