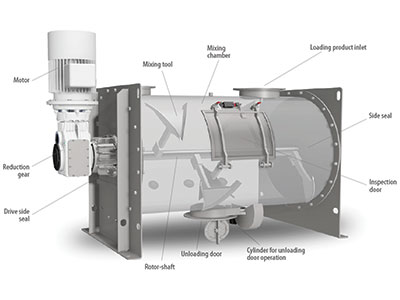

Plowshare mixer – Plough Shear Mixers (also named ploughshare mixers, plow mixers, plough mixers) consists of a cylindrical drums containing plough shaped mixing & drying with mounted Horizontal shafting. It creates a mechanical products fluidized bed drying & mixing with Short times. The Drying & mixing material coming from the wall into free spaces in a crisscross directions and inversely products materials back again. The plow separates and lifts the products materials into three-dimensional motions numbers and arrangements of insuring agitation back as well forth along the length of the vessels/ tanks/ mixing unit. The mixing actions is assisted by high speed chopper device independents high speeds motor with customized blades for adding shear to the product materials mix & drying .

Plough Shear Mixer machines is specially designed for ordered heavy duty mixing of both Dry and Wet materials. The special design of shovels / Plough with broad end and pointed tip facilitates goods penetrations and shuffling of mass within. Penetrations followed by agitations of the mass in quickly succession with the specially design blades result in homogeneity of powder mass both in dry and wet stage. Appropriate dough formations is reached in later processing.

Plough shear mixer machine Centrally mounting chopper unit will then operating to obtains wet granules of uniform sizes. Mixing homogeneous of mass for easily discharged from bottoms of the mixing drum provided with a flush fits discharging port / units.

Ploughshare mixer is equipped with many different auxiliary components like Jacket with Steam coil, Pressure Jacketed, Circulations jacket mediums, Sampling valves, high speed choppers, Temperature sensors, weighing system, dust removal system etc. We provides different jacketing systems with machines used for heating and cooling systems while, the temperatures should be maximum 200 Celsius degree. If required a small quantity of liquid is required during mixing with spraying or automations units is necessary in orders to mixing the liquid with the main ingredients. The liquid system is basically composed by the three parts pressure sources, liquids storage pot and spraying nozzles etc.

Advantages of Plough Shear Mixer machine , Ploughshare mixer

- High Speed and Homogenous Mixing & Drying

- Wide Range of Application

- Short Mixing & Drying Time

- Easy to Clean

- Avoid Agglomerations

Standard Features of Plough Shear Mixer – Ploughshare mixer

- Batch Capacity range from 100-30000 Liter

- Mild Steels /Stainless Steels constructions

- One end welded and one end bolted

- Temperature and Pressure for mixer & drying

- Gears Reducer Motor

- Mechanical seal / Gland Packing Seal + Air Purge Seal

- Pneumatic Operated Outlet Valves

Technical Specifications of Ploughshare Mixer

| Model | Gross Volume | Working Volume | Speed (RPM) | Motor Power |

| PM-100 | 100L | 40-60L | 101rpm (shaft) 1440rpm (chopper) |

3KW 1.5KW x 2 |

| PM-300 | 300L | 120-180L | 85rpm (shaft) 1440rpm (chopper) |

4KW 1.5KW x 2 |

| PM-500 | 500L | 200-300L | 85rpm (shaft) 1440rpm(chopper) |

7.5KW 1.5KW x 2 |

| PM-1000 | 1000L | 400-600L | 85rpm (shaft) 1440rpm (chopper) |

11KW 4KW x 2 |

| PM-1500 | 1500L | 600-900L | 85rpm (shaft) 1440rpm (chopper) |

15KW 4KW x 2 |

| PM-2000 | 2000L | 800-1200L | 85rpm (shaft) 1440rpm (chopper) |

18.5KW 4KW x 3 |

| PM-3000 | 3000L | 1200-1800L | 57rpm (shaft) 1440rpm (chopper) |

18.5KW 4KW x 3 |

| PM-4000 | 4000L | 1600-2400L | 57rpm (shaft) 1440rpm (chopper) |

22KW 4KW x 4 |

| PM-6000 | 6000L | 2400-3600L | 57rpm (shaft) 1440rpm (chopper) |

30KW 4KW x 4 |

| PM-8000 | 8000L | 3200-4800L | 42rpm (shaft) 1440rpm (chopper) |

45KW 4KW x 4 |

| PM-10000 | 10000L | 4000-6000L | 33rpm (shaft) 1440rpm (chopper) |

55KW 5.5KW x 5 |

| PM-12000 | 12000L | 4800-7200L | 30rpm (shaft) 1440rpm (chopper) |

55KW 5.5KW x 5 |

| PM-15000 | 15000L | 6000-9000L | 30rpm (shaft) 1440rpm (chopper) |

75KW 5.5KW x 5 |

| PM-20000 | 20000L | 8000-12000L | 30rpm (shaft) 1440rpm (chopper) |

90KW 5.5KW x 5 |

Ploughshare mixers, plow mixer & Dryer, plough mixer for Foods , Starch , Flavoring , Coffee , Chocolate , Nutraceuticals , Cosmetic , Pharmaceuticals , Detergent , Soaps , Metal Powders , Minerals , Friction Material, Ceramics , Agricultural Chemicals , Cement and Sand , Carbon black , Fire retardants , Talcum powders , Plough mixer is widely used to mix powder, granules, and small liquid additives in foods, chemicals, and construction line.