SIGMA KNEADER

offers the most extensive and innovative line of horizontal mixers and Sigma kneader used for mixing powder, dough, cream, batter, paste, sludge, slurries and granules for various applications such as the baking industry, pharma, ceramics, sealing compounds, metal powder, adhesives, brake lining, confectionery, carbon black, ceramic powders, grease, magnetic tape coatings, silicone rubber, soap & detergent.

Sigma Kneader’s advantage is that it delivers the special features and benefits that guarantee maximum production efficiencies, improved product and uniform processing-even with the stiffest of doughs.

You can depend on us for complete turnkey service. We will get your mixing system to you on-time, when you need it, and install it quickly. Your personnel will quickly learn how to operate and maintain your new equipment for optimal efficiency. We stand behind you with quality customer service long after the sale is completed. All at a competitive price.

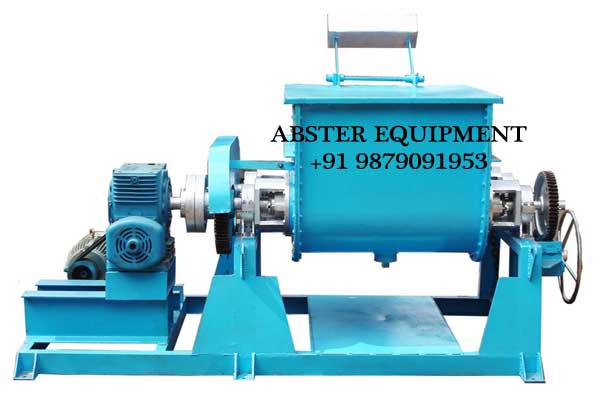

This machine comprises of a double ‘U’ shaped container welded and machined together inside which rotates two ‘Z’ shaped sigma blades in opposite directions. The clearances between the walls and the container are kept to a minimum to ensure maximum efficiency in kneading and mixing. The shafts of the sigma blades are fitted in bearing blocks which are each provided with roller bearings, steel glands/teflon rubber seals for smooth and leakless operations. The kneader is mounted on a sturdy base frame fabricated out of ISMC sections and are free from vibrations. For cooling and heating jackets are provided.

These types of machines are available in M.S. and S.S. construction. The kneader can be tilted by means of a mechanical system or manually and for bigger models beyond 250 Kgs we provided hydraulic tilting.

Hydraulic tilting system is provided with complete power pack, electric motor, pressure valves, pipes, fittings, cylinders and hoses which makes the tilting mechanism quick, easy and simple to operate.

The sigma kneader is a mixer designed to process highly viscous materials. It consists of two blades that rotate towards each other at the same or different speed inside a container. The twin screw basin kneading machine with two horizontally arranged kneading blades, which are deeply geared into one another and strip themselves reciprocally. Each blade moves the material in opposite direction thereby providing excellent cross mixing of all raw materials. The blades pass the trough walls and each other at close clearances resulting in good mixing. The close clearance produces a shearing and tearing action that is beneficial to the size reduction of solids. Selection of appropriate blade shape and speeds result in excellent mixing.

Application of Sigma Kneader

Sigma Kneader is having wide range of industry wise applications. It is uses for production of highly viscous materials like Chemical, Dyes & Pigments, Paints, Polymers Plastic, Polyester Putties, Plastics, Pharmaceuticals, Food products etc. We are giving here below industry wise sigma mixer uses:

Food & Confectionery: Processing of finely milled wheat flour, bechamel sauce, chocolate, bubble gum, biscuit doughs, sugar paste, Bakery Dough, Chewing gum, Compounded Hing, Asafetida, asafoetida, Sugar pastes, Biscuit dough.

Paint & Solvents: Kneading of polyester putty, glass putty, adhesives, sealants, Fiberglass resin doughs, Polyester Compounds, Flush Colors, Brake lining compounds, Resins, Adhesives

Rubber Products: Mixing of rubber solution & silicon rubber, Stiff pastes, Silicon Rubbers, Viscous rubber solutions, Sealing compounds, Butyl rubber

FMCG: Blending of Liquid Soap, Liquid Detergent, Soap Noodles, Soap & Detergent, Ceramics,

Other Applications: Printing ink, Dispersion of iron compounds, ceramic powders, Crayon and pencil lead, Gaskets and gland packings, Grinding wheel preparations, Hot-Melts, Inks and pigment products, Marzipan,, Mastics, Metal powders, Moulding preparations, Pencil erasers, Pharmaceuticals, Plastics, Putties, Refractories, Magnetic Tape Coatings, Ceramics, Carbon Black, Carbon pastes, PVC coatings, Rubber Compounds, Fiber Glass, Grease, Lead Storage Battery, Zirconium Crucibles dough sigma mixer, Solid propellants

Working Principle of Sigma Kneader

In Sigma Kneader mixer tangential action of mixing and kneading obtained by ‘Z’ type (SIGMA) shaped kneading blades, which rotates very accurately at different speed towards each other causing product to be transferred from one end to another end. Discharge of the finished product is achieved by tilting the container or through the valves at the bottom or by means of an extrusion screw beside the container.

The mixing action is a combination of bulk movement, stretching, folding, dividing, and recombining of the material. The shearing & tearing action of the material against blades and the side walls causes size reduction of the solids. After the time period required for sterilizing the batch has elapsed, the heating circuit shuts of the pneumatic damper (exhaust) opens and cooling operation commences.

In the tangential design, the blades rotate in the trough meeting tangentially. The front blade generally rotates faster than the rear blade usually in the ratio of 3:2. Tangential blades are generally used for material of higher viscosities such as adhesives, rubber compounds, flush colors, dyes, and pigments.

In the overlapping design, the blades overlap above the saddle of the container. Due to the overlapping action, it is necessary that the relative position of the two blades is unchanged, and as a result, both the blades rotate at the same speed. Materials that flow freely or creep down into the blades are mixed using the overlapping blade action. This design offers a faster interchange of material from one blade compartment of the mixer to the other. Overlapping blade action is used for materials of lighter viscosity such as carbon pastes, clay coating, creams, and ointments. The overlapping blade produces a lower kneading and shearing compared to the tangential blade action.

Technical Specification of Sigma Mixer

| Model | Capacity – Liters | Motor (H.P.) | ||

| Working Capacity approx. | Gross Capacity approx. | General | Heavy Duty | |

| ASM – 50 | 50 Liters | 80 Liters | 5 H.P. | 7.5 H.P. |

| ASM – 75 | 75 Liters | 110 Liters | 7.5 H.P. | 10 H.P. |

| ASM – 100 | 100 Liters | 150 Liters | 10 H.P. | 15 H.P. |

| ASM – 150 | 150 Liters | 200 Liters | 15 H.P. | 20 H.P. |

| ASM – 200 | 200 Liters | 300 Liters | 20 H.P. | 25 H.P. |

| ASM – 400 | 400 Liters | 550 Liters | 30 H.P. | 40 H.P. |

| ASM – 500 | 500 Liters | 750 Liters | 40 H.P. | 50 H.P. |

| ASM – 750 | 750 Liters | 1150 Liters | 50 H.P. | 60 H.P. |

| ASM – 1000 | 1000 Liters | 1500 Liters | 60 H.P. | 70 H.P. |

| ASM – 1500 | 1500 Liters | 2100 Liters | 75 H.P. | 80 H.P. |

| ASM – 2000 | 2000 Liters | 2600 Liters | 80 H.P. | 90 H.P. |

| ASM – 3000 | 3000 Liters | 3800 Liters | 100 H.P. | 120 H.P. |

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.

Send Inquiry