Sigma Kneader Mixer Manufacturers in Goa – Suppliers & Exporters in Goa

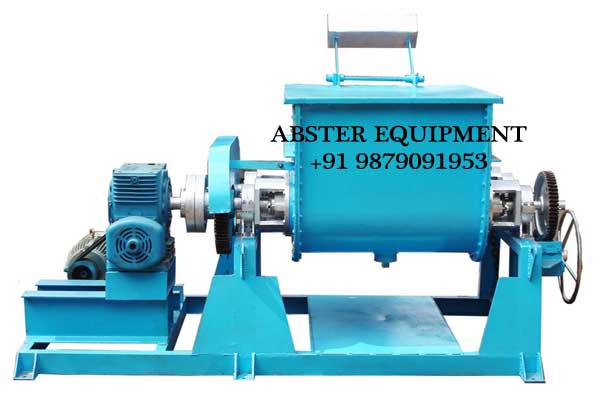

Abster Equipment are the most leading Manufacturers, Suppliers, Exporters of Sigma Kneader Mixer in Goa. We provide durable, portable and best quality sigma kneader mixer for mixing of various viscous materials. These viscous materials can be dough, polymers, rubber, erasers, chewing gum, adhesives, ink, crayon etc. They can be mixed with reactants like liquids, powders or slurries.

We offer a wide range of sigma mixer with different models, sizes/dimensions, storage capacity and power as per customer’s requirements. Their sigma kneader mixer is available in both single arm and twin shaft design. The Single arm sigma kneader mixer is commonly used in the food and bakery industry.

Construction and Design Sigma Kneader Mixer

Sigma kneader mixer consists of blades, discharge screw, container walls, hydraulic cylinder, liner plates and jacket. A jacket arrangement on a sigma mixer is used for heating and cooling applications. All these parts are made with materials used in stainless steel.

We manufactured a sigma mixer in horizontal form with W & Z shaped blades. At the mixing process, these blades rotate towards each other. A discharged screw is mounted below the blades through which mixed materials are discharged.

Market Demands For Sigma Kneader Mixer

As per industry norms and standards, we provide a premium quality sigma kneader mixer in compliance to meet international standards. So we are widely accepted as a Sigma mixer manufacturer in the markets. Our mixers are commonly used in the various industries like chemical, rubber factories, food industry, sugar plants, ceramics factory, powder coating industry, pharmaceuticals and many more.

Key Features

- Requires less time for mixing

- Portable

- Durable

- Corrosion resistant blades

- Applicable for high viscosity materials

- Integrated with charging system

- High performance and efficiency

- Charging and discharging through butterfly valve

- Quick, easy, reliable and safe operation

Applications

Ceramics, refractories, sugar pastes, polymer and rubber, strapping rolls, chemicals, plastics, putties, metal powders, soaps, creams, biscuits etc

Working Principle of Sigma Mixer

In Sigma mixer tangential action of mixing and kneading obtained by ‘Z’ type (SIGMA) shaped kneading blades, which rotates very accurately at different speed towards each other causing product to be transferred from one end to another end. Discharge of the finished product is achieved by tilting the container or through the valves at the bottom or by means of an extrusion screw beside the container.

The mixing action is a combination of bulk movement, stretching, folding, dividing, and recombining of the material. The shearing & tearing action of the material against blades and the side walls causes size reduction of the solids. After the time period required for sterilizing the batch has elapsed, the heating circuit shuts of the pneumatics damper (exhaust) opens and cooling operation commences.

In the tangential design, the blades rotate in the trough meeting tangentially. The front blade generally rotates faster than the rear blade usually in the ratio of 3:2. Tangential blades are generally used for material of higher viscosities such as adhesives, rubber compounds, flush colors, dyes, and pigments.

In the overlapping design, the blades overlap above the saddle of the container. Due to the overlapping action, it is necessary that the relative position of the two blades is unchanged, and as a result, both the blades rotate at the same speed. Materials that flow freely or creep down into the blades are mixed using the overlapping blade action. This design offers a faster interchange of material from one blade compartment of the mixer to the other. Overlapping blade action is used for materials of lighter viscosities such as carbon pastes, clay coating, creams, and ointments. The overlapping blade produces a lower kneading and shearing compared to the tangential blade action.

Technical Specification of Sigma Mixer

| Model | Capacity – Liters | Motor (H.P.) | ||

| Working Capacity approx. | Gross Capacity approx. | General | Heavy Duty | |

| ASM – 50 | 50 Liters | 80 Liters | 5 H.P. | 7.5 H.P. |

| ASM – 75 | 75 Liters | 110 Liters | 7.5 H.P. | 10 H.P. |

| ASM – 100 | 100 Liters | 150 Liters | 10 H.P. | 15 H.P. |

| ASM – 150 | 150 Liters | 200 Liters | 15 H.P. | 20 H.P. |

| ASM – 200 | 200 Liters | 300 Liters | 20 H.P. | 25 H.P. |

| ASM – 400 | 400 Liters | 550 Liters | 30 H.P. | 40 H.P. |

| ASM – 500 | 500 Liters | 750 Liters | 40 H.P. | 50 H.P. |

| ASM – 750 | 750 Liters | 1150 Liters | 50 H.P. | 60 H.P. |

| ASM – 1000 | 1000 Liters | 1500 Liters | 60 H.P. | 70 H.P. |

| ASM – 1500 | 1500 Liters | 2100 Liters | 75 H.P. | 80 H.P. |

| ASM – 2000 | 2000 Liters | 2600 Liters | 80 H.P. | 90 H.P. |

| ASM – 3000 | 3000 Liters | 3800 Liters | 100 H.P. | 120 H.P. |

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.