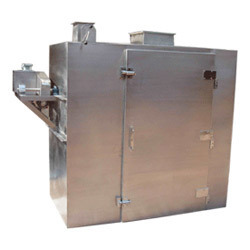

Tray Dryer GMP Model – tray dryer Working Principle with 12 tray dryer, 24 tray dryer 48 tray dryer, 96 tray dryer, 192 tray dryer, Hot Air tray dryer. Cabinet tray dryer and Vacuum tray Dryers with stainless Steel contact parts 304 and 316 , 316 L.

Tray Dryer Applications :

Tray Dryers is ideally suitable for drying chemicals & pigments, pharmaceuticals & API, plastic and raisins, food, engineering, defense, spices, and herbs, chilies, spices, papads, potato chips, onions, fish, garlic, grapes, cashew nuts, confectionery, macaroni, wood, ceramics, plastics, and metalworking, to dry and cure coatings, paints, and adhesives etc. It is also for used for drying pharmaceuticals, chemicals, powders, granules, plastic granules etc. Heating is either by electric or steam or both combined. for economical drying of granules, powder, food, flavor, color, and nutrients of the food material & chemicals including pigments, dyes, and pesticides.

Tray Dryer Usage:

Tray Dryer is used for the best drying results in conventional process liquid or wet cake, powder, granule, Pigment, Foods, Bakery, Electrodes, Chemicals, and Plastic applications & demand for tray dryer machine market growth. In addition to specific this, food processing is amongst a leading industry using tray dryers’ machine for drying spice, chilies, onion, fish, potato chip, grape, garlic, confectioneries and many more food items in food processing units, etc. Heating Media: Electric, Steam & Thermic Fluid.

Description:

- Industrial tray dryer Steam Operated 30’c To 100’c G.M.P. Model With S.S. 304 Externals & S.S. 316L Internals.

Salient Features:

- Construction:

- EXTERNAL: 2MM THK INTERNAL: 2MM THK

- MOC: CGMP

- Surface Finish:

- EXTERNAL: Buffed to 150 grit matt finish INTERNAL: Buffed to 220 grit mirror finish.

- Inlet & Outlet:

- All dryers have a 5 micron pre filter r at the inlet and a manually infinite adjustable damper at the outlet.

- Door:

- Doors at provided at the front and / or rear side of the dryer. Door lips are lined with silicon rubber gasket to prevent any leakages. Suitable locking is provided for the doors.

- Air Circulation:

- Air circulation is done by specially designed re-circulation blowers inside the dryer. The blower capacity, static & design depends on the size and model of dryer.

- Heating:

- Dryers are normally supplied with steam/ electric/ thermo fluid / hot water heating system. Suitable heating coils / clarifiers are provided in the dryers.

- Temperature Control:

- Temp control system is done by electronic digital temp controller fitted in the control panel. The temp control in the dryer is fully automatic.

- Trays:

- Trays are available in S.S. 304/ 316 q. All trays are fully die pressed and with coves corners. Trays are buffed to mirror finish. Trays are also available in aluminium / Polypropylene / Frap/ M.S. galvanized as per clients requirements.

- Trolley:

- Trolley is provided in the dryers to accommodate trays in it. Trolley trucks are used to load and unload the trays into the dryer.

- Control Panel:

- Automatic Control panel is fitted on the side of the dryer. If consists of Starters, contactors, safety relays, ckt breakers, indicating lamps, push buttons , timers, controllers etc.

Technical Details:

| Model No. | TD-12 | TD-24 | TD-48 | TD-96 | TD-192 |

| Loading capacity | 12 Trays | 24 Trays | 48 Trays | 96 Trays | 192 trays |

| External Dim. in mm | 1370 (W) x 530 (D) x 940 (H) | 1370 (W) x 940 (D) x 940 (H) | 1980 (W) x 1020 (D) x 1880 (H) | 3320 (W) x 1900 (D) x 1880 (H) | 3320 (W) x 1900 (D) x 1880 (H) |

| Internal Dim. In mm | 840 x 430 x 840 | 840 x 860 x 840 | 1020 x 930 x 1830 | 1960 x 930 x 1830 | 1960 x 930 x 1830 |

| No of Doors | One | One | One | Two | Two |

| No of Blowers | One | Two | One | Two | Four |

| No of motors / HP | 1 / 0.5 HP 3 Phase 415 V | 1 / 0.5 HP 3 Phase 415 V | 1 / 1 HP 3 Phase 415 V | 2 / 1 HP 3 Phase 415 V | 4 / 1 HP each 3 Phase 415 V |

| Electrical Heating Load for100°C / 200°C / 300°C | 3kw / 6kw / 9kw | 6kw / 9kw / 12kw | 9kw / 15kw / 18kw | 15kw / 21kw / 27kw | 36kw / 42kw / 48kw |

| Steam Heater No. of coils. | 2 | 2 | 2 | 2 | 2 |

| Steam Pressure | 3.3 Kg / Cm2 | 3.3 Kg / Cm2 | 3.3 Kg / Cm2 | 3.3 Kg / Cm2 | 3.3 Kg / Cm2 |

| Steam consumption | 25 LBS / Hr | 45 LBS/Hr | 60 LBS / Hr | 80 LBS / Hr | 120 LBS / Hr |

| Insulation in mm 100°C / 200°C / 300°C | 50 / 75 / 75 | 50 / 75 / 75 | 50/75/75 | 50 / 75 / 75 | 50 / 75 / 75 |

| No of Trolleys | Rack System | Rack System | One | Two | Four |

| Tray Size | 812 x 406 x 31 | 812 x 406 x 31 | 812 x 406 x 31 | 812 x 406 x 31 | 812 x 406 x 31 |

| Trolley Dimension | Fixed Racks | Fixed Racks | 840 x 960 x 1780 | 840 x 960 x 1780 | 840 x 960 x 1780 |

| Note: Dimensions & Technical Details are subject to change as per customers’ requirement without any further notice | |||||

Our Range Hot Air Tray Dryer 12 Trays Dryer Machine, 24 Trays Dryer Machine, 48 Trays Dryer Machine, 96 Trays Dryer Machine, 192 trays Dryer Machine and more we can designed as per customer requirement GMP / USFDA Standard.